- MENTOR GRAPHICS EXPEDITION PCB CRACK ACTIVATION KEY

- MENTOR GRAPHICS EXPEDITION PCB CRACK FULL CRACK

- MENTOR GRAPHICS EXPEDITION PCB CRACK VERIFICATION

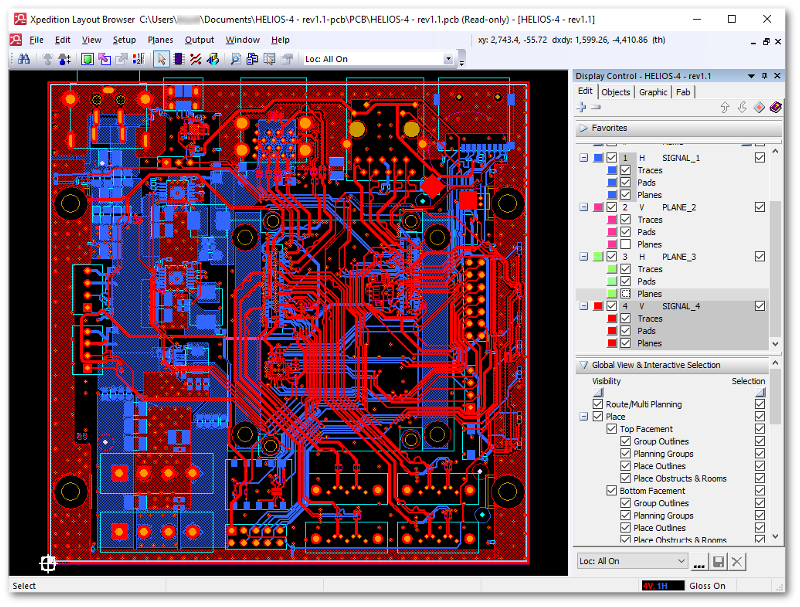

Mentor Graphics HyperLynx VX Full Crack allows for the efficient generation of entire package models with multi-processing for quicker turnaround time. As a result, you can accomplish more innovation, shorter time-to-market, and lower expenses. It enables hardware design engineers and PCB designers to study, identify, fix, and verify significant design problems, lowering design cycle times and enhancing product dependability. It is simple to use and include in your workflow.

MENTOR GRAPHICS EXPEDITION PCB CRACK VERIFICATION

Mentor Graphics HyperLynx VX With Crack provides a comprehensive set of design analysis and verification applications to address the demands of PCB engineers at any stage of the board design process.

MENTOR GRAPHICS EXPEDITION PCB CRACK ACTIVATION KEY

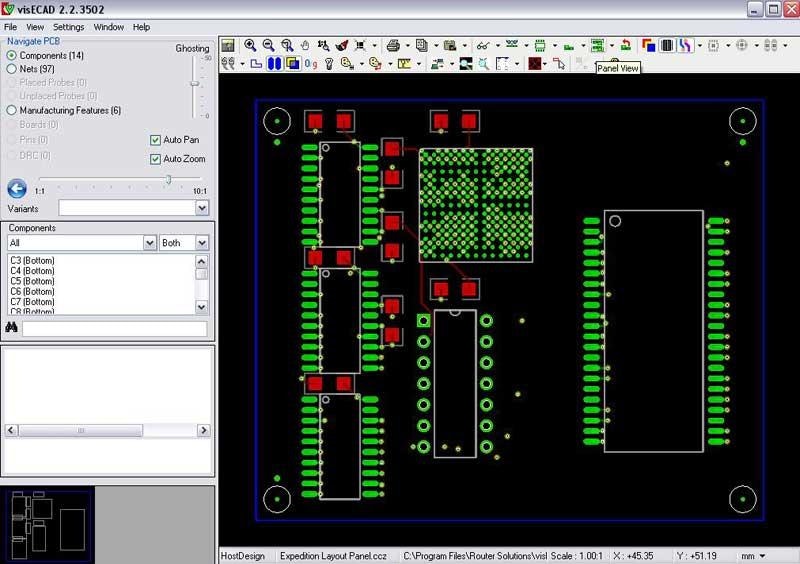

You can also download: ESSS Rocky DEM Crack Mentor Graphics HyperLynx VX Crack Plus Activation Key It provides users access to database objects through the Object Automation Model and also enables them to execute complex geometric operations on the topics. It supports PCB design assessment for EMI/EMC, signal integrity, power integrity, and other concerns. The program has tremendous and complex capabilities, such as managing rules, definitions, credentials, and more. Mentor Graphics HyperLynx VX Key is a complete solution for engineers since each design has flaws and defects that may result in negative evaluations, which no one wants. Furthermore, the analysis helps developers to determine any faults with circuit designs and rectify them, hence avoiding recurrent expenses. The program enables users to meet their PCB design needs while also making the workflow process faster and more flexible. With pins placed, modify the Placement, Assembly, and Silkscreen outlines to meet the datasheet specifications.Mentor Graphics HyperLynx VX Crack is an excellent program that provides customers with a comprehensive collection of analytic tools for accurate analyses of their designs and projects.Consequently, the pin one location will be ½ of the total length and width of the pins. Note: Optimum’s standard for component origins calls for the origin at the center of component body for surface mount parts.Enter the X-Y coordinate where Pin 1 of the component should be, and click Ok.

Press the X-Y Place button at the bottom of the Cell Editor screen (hotkey: F3).The Place Pins dialog will close, and an outline of all pins in their correct pattern will be following your mouse. Enter the relevant data (see image) and click ok. For a more thorough look into this tool, see our Tutorial here. To re-place the pins, we’ll be utilizing the Parameter Place option.Note: You must hold the Shift key when selecting the Padstack to apply the change to all selected pins simultaneously.

0 kommentar(er)

0 kommentar(er)